Abstract: Continuous cooling is a mandatory requirement by UPTIME Institute (UTI) for the certification of all Tier-IV datacenters. Thermal Energy Storage Tanks (TES) are very common engineering solution to provide the adequate buffer for this purpose and to comply with UTI requirement (TES tanks are also recommended by UTI and are becoming standard industry practice for all Tier-III data centers with high density IT racks. However, there is much more than continuous cooling that the data center owners & operators can benefit from TES tanks to reduce their annual operating costs.

Thermal Energy Storage Tanks and its application in Data Centers:

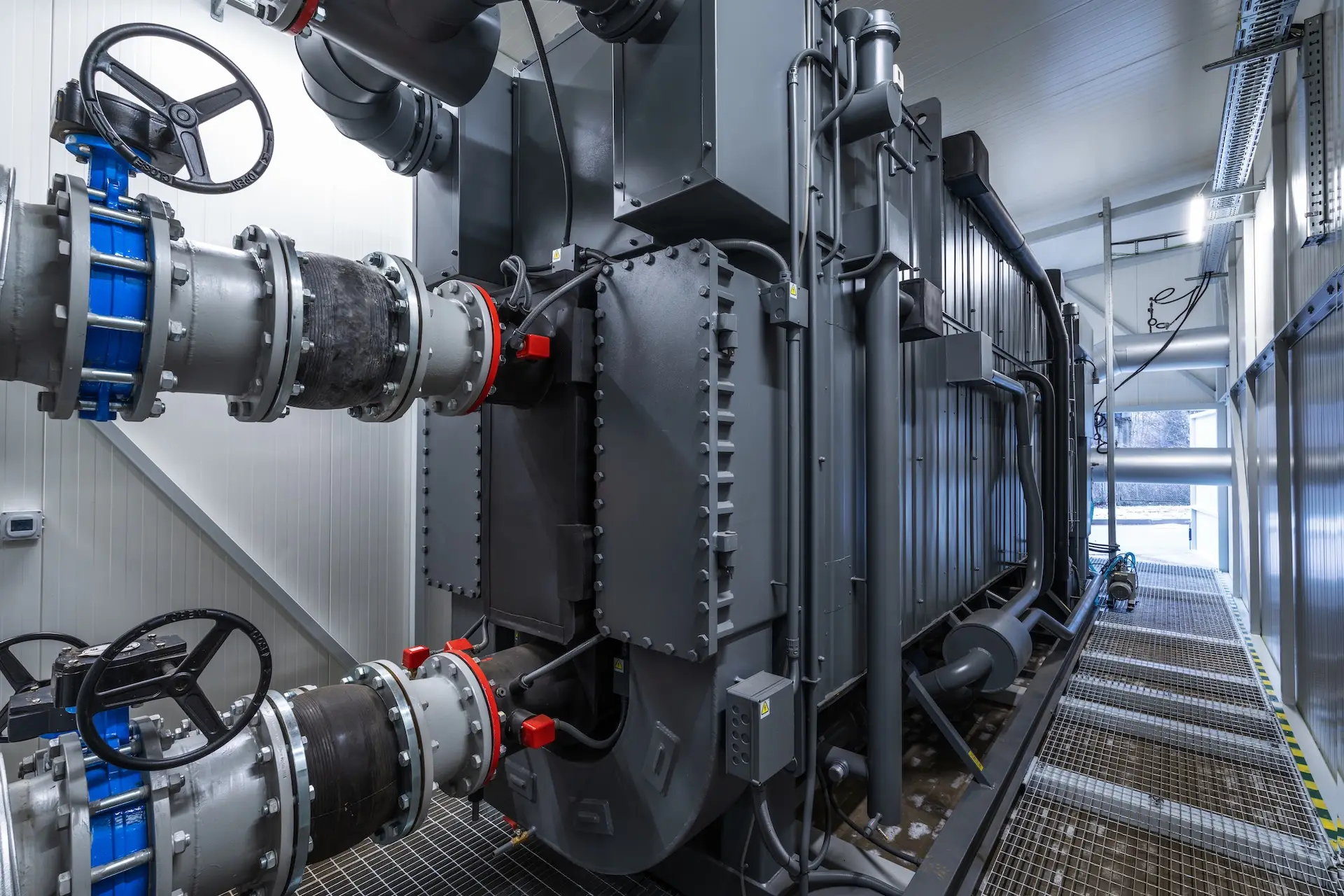

Continuous cooling is a mandatory requirement by UPTIME Institute (UTI) for all Tier-IV data centers. Thermal Energy Storage (TES) Tanks are the best way of complying with this requirement in most of the cases (except for designs with DX-Units e.g. CRAC in data halls). So redundant TES tanks with concurrently maintainable and fault tolerant configuration for piping and control shall be provided as a result. Furthermore, providing TES tanks in Tier-III data centers are highly recommended by UTI for high density IT racks (more than 5kW/rack) and is becoming more and more adopted by many data center owners and operators for increased resiliency.

In conventional designs, usually a large enclosed steel buffer tank is provided with enough capacity to provide continuous cooling for the IT equipment in event of power failure and until the generators (in case of grid power is main source of power) are started and chiller resume to their full cooling capacity.

These tanks are usually bulky, occupy space/land and have high fabrication costs and yet may only be used for a few times during the whole life cycle of a data center; however a smarter way would be to modify the design slightly and use them more frequently (e.g. daily) instead of occasional use to enhance the power efficiency and energy saving in data centers which will subsequently result in lower operational costs.

Obviously the below proposed application may not be applicable in some certain cases and this shall be studied case by case for each project with respect to its climatic condition, day/night temperature variations, cooling load profiles, existence of other free cooling and chiller-less systems in the design, etc. Contrary to common belief, data center cooling load profiles are not necessarily flat (100% full load) all the time and the actual operating data shows fluctuations (with highs and lows) in the cooling profile depending on the application and nature of IT loads; additionally even if the cooling load shows 100% full in some applications, the weather temperature profile is NOT Flat and we will see temperature fluctuation during days and nights at site location; this will give the designer a window of opportunity to use the thermal energy storage more wisely and take complete advantage of all the benefits of it.

Stratified Thermal Energy Storage Tanks are excellent and economical (compared to batteries) way for holding energy in form of chilled water; by using these fluctuations in cooling load profiles and ambient dry / wet bulb temperature we can charge the TES tank during hours when:

- cooling system can operate more efficiently (less kW/TR)

- there is increase in chiller cooling capacity (low dry/wet bulb temp.)

- cooling load demand is low (chillers operating at partial load)

and discharge when:

- cooling system is less efficient (high kW/TR)

- chiller cooling capacity is lower (high dry/wet bulb temp.)

- cooling load demand is at peak (one or more chillers can be switched off completely and still meeting peak load)

These discharging/charging modes can always be completely automated using SCADA/PLC to guarantee the most optimum & efficient operating condition.

Any additional capital cost due to the increased TES capacity and the automation system can be studied for each project using financial modeling to prove its viability and return on investment which can be offset by annual electricity consumption savings.

The UTI Tier requirement for continuous cooling can still be fulfilled using the same tank to ensure that the tanks are NEVER discharged below the minimum threshold capacity (by monitoring the thermocline level in the tank) which is the minimum capacity required to always remain in the tank for “continuous cooling”.

Design Notes & Benefits:

- TES Tank Sized for 4 hours of full cooling capacity storage as compared to 10 to 15 minutes of current common practice. i.e. if a data center with IT load of 4,000 kw would typically require 5,200 to 5,600 KW (1.3 to 1.4 x IT load) of cooling capacity and hence the thermal storage capacity should be 4 Hrs. x 5,600 kw = 22,400 kwh or 6,370 Ton-Hr.

- Currently utilized to provide continuous cooling via dedicated small power chilled water pumps linked to the UPS.

- Compared to buffer tanks, provide more stable chilled water supply temperature for around 80% to 90% of the tank volume.

- Should be oversized and used in daily operation routine to produce chilled water at night and avoid part load chillers operation.

- Preferably open to atmosphere and at least 2 m higher than the highest CRAH, FCU or AHU coil.

- Can be put in the basement but require complex sustaining valves’ and dedicated pumps and controls arrangement.

- Can be pressurized but require thicker steel and critical diffuser design. Experience is insufficient and usage is extremely rare.

- Cold and warm diffusers require 450 mm height each and thermocline is typically 600 mm in height and hence around 1.5 m of the height of water Colum is unutilized.

- Thermal losses are around 1% a day and requires walls, bottom and roof insulation of at least 100 mm thick.

- Additional water storage can be used as fire protection storage tanks (subject to local codes and regulation)

- Atmospheric tank will act as expansion tank and pressurizing system.

Phase-Change-Material (PCM) TES Tanks:

PCM TES Tank volume can be reduced by 3-4 times compared to water TES tank which will take much smaller foot print. However more extensive study and actual field results and tests are required to further confirm and adopt at larger scale.