Introduction

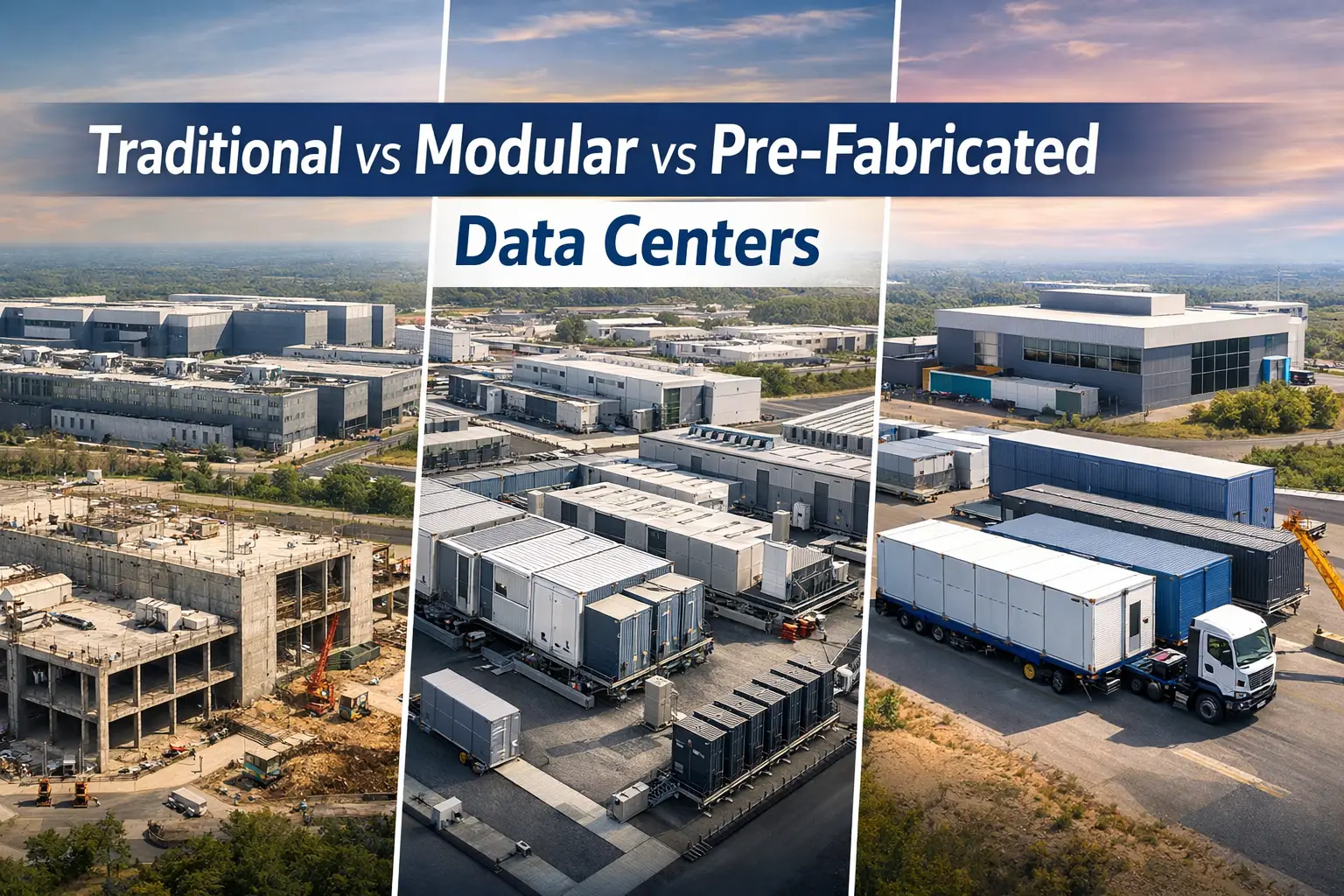

Zero Liquid Discharge (ZLD) is an advanced water management strategy aimed at eliminating liquid waste discharge from industrial and commercial facilities. With its ability to recover usable water and reduce waste, ZLD is emerging as a transformative solution in regions with water scarcity, such as the Middle East. The increasing need for sustainable water management has driven the adoption of ZLD across various industries, including district cooling systems and data centers.

Feasibility Assessment: While ZLD offers substantial benefits, its adoption requires a detailed feasibility study for each project.

Traditional wastewater treatment methods often fall short in addressing the challenges posed by high salinity, complex effluent compositions, and stringent environmental regulations. ZLD bridges these gaps by integrating advanced technologies, such as membrane-based reverse osmosis (RO) and thermal crystallization, to achieve near-total water recovery. This comprehensive approach not only minimizes environmental impact but also aligns with the United Nations Sustainable Development Goals (SDGs) by promoting resource efficiency and sustainability.

ZLD as a Solution

ZLD systems address the challenges of managing industrial wastewater by integrating advanced technologies to minimize waste and recover water efficiently. Key components include:

- Water Recovery: ZLD systems recycle blowdown water for reuse, reducing dependence on external water sources.

- Solid Waste Management: Concentrated brine is crystallized into solid waste, simplifying transportation and disposal.

- Energy Integration: ZLD can be economically optimized when integrated with on-site power generation and heat recovery systems.

Advantages and Limitations of Zero Liquid Discharge Techniques

Technologies for ZLD

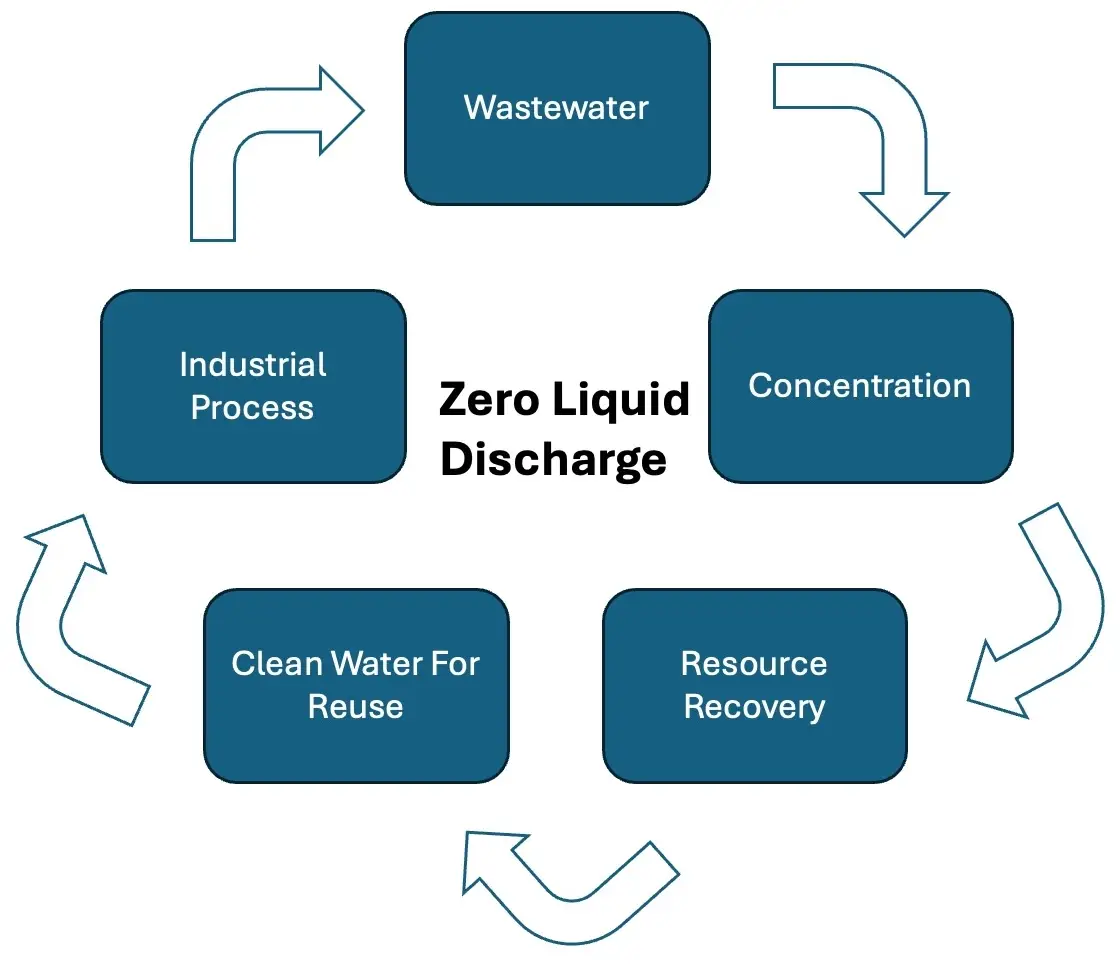

- Pre-Treatment: Removes large particles and organic contaminants, ensuring efficient operation of downstream equipment. Pre-treatment may include filtration, pH adjustments, and chemical conditioning to prevent scaling and fouling during subsequent processes.

- Membrane Processes: Technologies like reverse osmosis (RO) and nanofiltration are commonly used as preconcentration steps. Membrane-based systems can reduce the volume of brine significantly before sending it to thermal concentrators, thus lowering energy consumption and operational costs. Recent advancements, such as closed-circuit reverse osmosis (CCRO), further enhance recovery rates and operational efficiency.

- Evaporation and Crystallization: Thermal technologies recover water and convert waste into solid form, with energy-efficient options like mechanical vapor recompression (MVR). These processes are essential for managing high-salinity brine and recovering valuable byproducts like salts.

Membrane-Based ZLD as a - Membrane-Based ZLD as a Pre-concentrator: The integration of RO systems as Pre-concentrators significantly reduces the energy demand of thermal ZLD processes. For instance, RO can concentrate wastewater to a level that reduces thermal treatment volumes by 60% to 70%, as demonstrated in leading industrial applications globally.

- Sludge Management: Final solid waste is treated and disposed of in compliance with environmental regulations, or reused if possible, adding value to the waste management chain.

Applications For District Cooling and Data Centers

1. District Cooling Systems

District cooling systems require significant water resources for heat dissipation, often relying on treated sewage effluent (TSE) as makeup water. The use of TSE introduces challenges such as high levels of dissolved solids, leading to increased blowdown volumes and salinity issues. By integrating ZLD, district cooling plants can:

- Reduce blowdown discharge to municipal systems.

- Recycle and reuse water, enhancing water sustainability.

- Minimize environmental impact in water-scarce regions by recovering high-purity water and valuable salts.

2. Data Centers

Data centers, particularly hyperscale facilities and data parks, consume vast quantities of water for cooling. Challenges such as limited land availability for evaporation ponds and high salinity from blowdown water necessitate innovative solutions. ZLD systems enable data centers to:

- Achieve compliance with strict environmental regulations.

- Reduce operational risks by minimizing water wastage.

- Utilize server-generated heat in ZLD processes, enhancing energy efficiency.

- Address scalability needs for large-scale operations, ensuring sustainable water management practices.

The challenges associated with cooling tower operations, such as high salinity blowdown, are effectively mitigated by ZLD. Integrating membrane-based preconcentration technologies allows these facilities to achieve higher recovery rates and reduce dependence on external water supplies.

Membrane-Based ZLD System: An Application Example

A notable example of membrane-based ZLD implementation involves using reverse osmosis systems as Pre-concentrators. Wastewater is first treated with advanced RO membranes, achieving high recovery rates while significantly reducing the volume of brine sent to subsequent thermal stages. This approach reduces energy demand by approximately 50% and operational costs by nearly 30%, as highlighted in industrial projects like those implemented in China’s hyperscale data centers.

Case-Specific Feasibility Assessment

While ZLD offers substantial benefits, its adoption requires a detailed feasibility study for each project. Critical factors include:

- Water quality and volume requirements.

- Capital and operational cost analysis.

- Site-specific constraints such as land availability and energy integration.

- Compatibility with existing infrastructure.

Conclusion

Revolutionizing Water Management for District Cooling & Data Centers

Discover how advanced ZLD systems reduce costs, conserve resources, and achieve next-level sustainability in high-demand industries.

Contact Us Today!

Next Steps

Azura Consultancy specializes in designing and implementing ZLD systems tailored to the unique requirements of district cooling and data center projects. We provide:

- Comprehensive feasibility studies and technical assessments.

- Design and engineering solutions using state-of-the-art tools.

- End-to-end project management, from construction to commissioning.

Contact us to explore how ZLD can enhance the sustainability and efficiency of your projects. Together, we can pave the way for a water-efficient and environmentally responsible future.

FAQ For Zero Liquid Discharge

1. What is the zero discharge principle?

2. What is Zero Liquid Discharge (ZLD)?

3. Why is Zero Liquid Discharge relevant to District Cooling?

4. Why is Zero Liquid Discharge relevant to Data Centers?

5. What is the stage for zero discharge?

The term “stage for zero discharge” typically refers to the overall sequence of treatment and concentration processes culminating in near-complete reclamation of water. Commonly, this sequence includes:

- Pretreatment (removing larger contaminants)

- Primary treatment (clarification, filtration)

- Advanced treatment (membrane filtration, reverse osmosis)

- Concentration and crystallization (evaporators, crystallizers)

In this final stage, dissolved solids become a solid or slurry, leaving virtually no liquid to be discharged.

6. Which technologies are commonly used in Zero Liquid Discharge systems?

ZLD systems commonly rely on:

- Reverse Osmosis (RO): to remove dissolved solids and impurities from wastewater.

- Evaporators: to concentrate the brine.

- Crystallizers: to produce solid salts or crystals from concentrated brine.

- Thermal or mechanical vapor recompression: to increase efficiency of evaporation.

In District Cooling plants or water-cooled data centers, RO and evaporators are especially popular for treating cooling-tower blowdown and reusing the reclaimed water.

7. What are the disadvantages of zero liquid discharge?

While beneficial for water sustainability, ZLD has challenges:

- High capital and operating costs: Evaporators, crystallizers, and advanced filtration systems can be expensive.

- Energy intensity: Concentrating and crystallizing wastewater requires substantial energy.

- Complex maintenance: Specialized knowledge is needed to run ZLD equipment effectively.

- Disposal of solid waste: The final solid byproduct must be handled properly, sometimes requiring landfilling or further processing.

8. Can ZLD be integrated with renewable energy sources?

9. How does Zero Liquid Discharge support sustainability and ESG goals?

Many organizations emphasize Environmental, Social, and Governance (ESG) targets. A ZLD system strengthens these commitments by:

- Conserving water: lowering freshwater intake.

- Eliminating effluent: reducing risks of pollution or regulatory fines.

- Demonstrating responsible resource management: showcasing proactive environmental stewardship.

10. What factors should be considered before implementing ZLD?

- Water chemistry (dissolved salts, metals, organics).

- Flow rate and composition of wastewater streams.

- Energy costs and carbon intensity of local power grids.

- Regulatory landscape (local discharge limits, disposal regulations for solids).

- Project ROI and total cost of ownership.

In District Cooling or Data Center cooling, analyzing blowdown composition and evaluating synergy with existing water treatment systems is key.

11. Are there alternatives if a full ZLD system is not feasible?

Yes. Options include:

- Near-ZLD: Where only a minimal, concentrated liquid brine requires disposal.

- Reuse & partial treatment: Treating part of the wastewater for reuse without fully eliminating liquid discharge.

- Hybrid systems: Combining advanced filtration with partial discharge for more cost-effective operations.

For District Cooling and Data Centers, partial reuse of cooling-tower blowdown for other on-site applications (e.g., landscaping, toilet flushing) can still yield meaningful water savings.